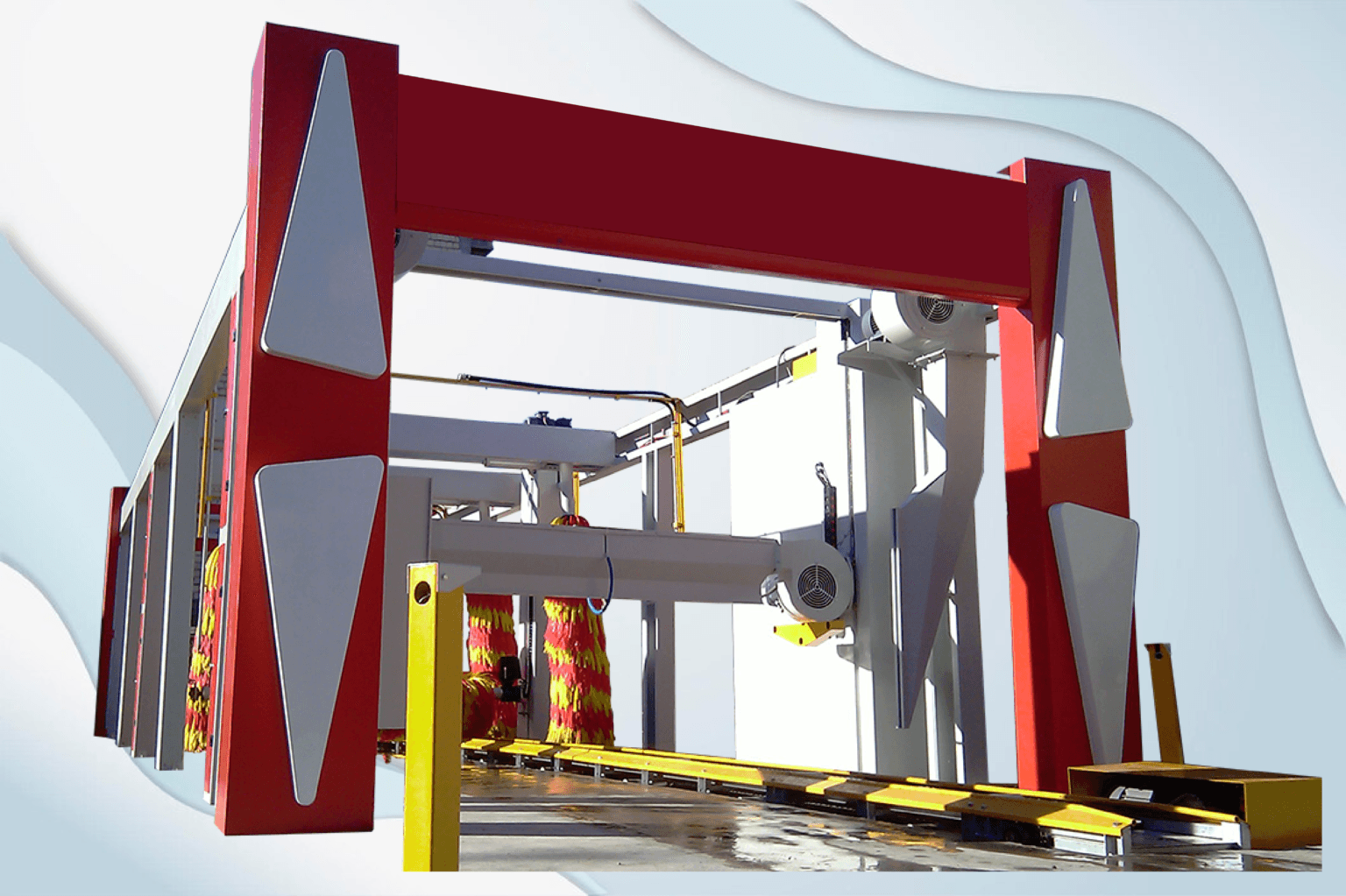

Keeping Uptime ≥98% with a 6-Month Warranty & Smart Maintenance: 7 Proven Tactics

Daily/weekly/monthly routines, spares strategy, remote support, and SLAs that keep your wash lane earning every hour.

Insights

Apr 22, 2025

1) Standardize daily routines

Walk-around inspection; check brushes/arms, hoses, rails, leaks.

Clean sensors and lenses; verify e-stops.

Empty grates and mud traps; log panel warnings.

2) Calibrate weekly

Nozzles, angles, and spray coverage.

Chemical dosing against water hardness and temperature.

Dryer blade spacing and timing.

3) Go deeper monthly

Lubricate bearings, check gearbox levels.

Rail/roller alignment and fastener torque.

Thermal scan (if available) on panels to spot hot connections early.

4) Build a “72-hour spares kit”

Keep on site: sensors, belts, nozzles, seals, key fuses/relays, a spare dosing pump, and common fasteners. The goal: fix in hours, not days.

5) Track the right KPIs

Uptime %, Cycle time, MTBF (mean time between failures), MTTR (mean time to repair).

Monthly trend reviews drive targeted maintenance and training.

6) Use your warranty wisely

Europe Makine’s 6-month warranty covers manufacturing defects (parts & labor). Pair it with a response-time SLA (e.g., 4/8/24-hour windows by severity) and remote diagnostics to accelerate troubleshooting.

7) Train for turnover

Create a 30-minute shift-start checklist, a 2-page quick reference for fault codes, and a quarterly refresher on chemical safety and emergency procedures. Training offsets staff rotation and keeps standards consistent.

The business impact

Each 1% uptime improvement in a busy site often equals dozens of extra paid washes per month.

Preventive maintenance is cheaper than lost queue hours and reputational damage.

CTA: Want a site-specific maintenance pack and spares list? Contact Europe Makine—we’ll map your usage pattern to a practical plan.

More to Discover

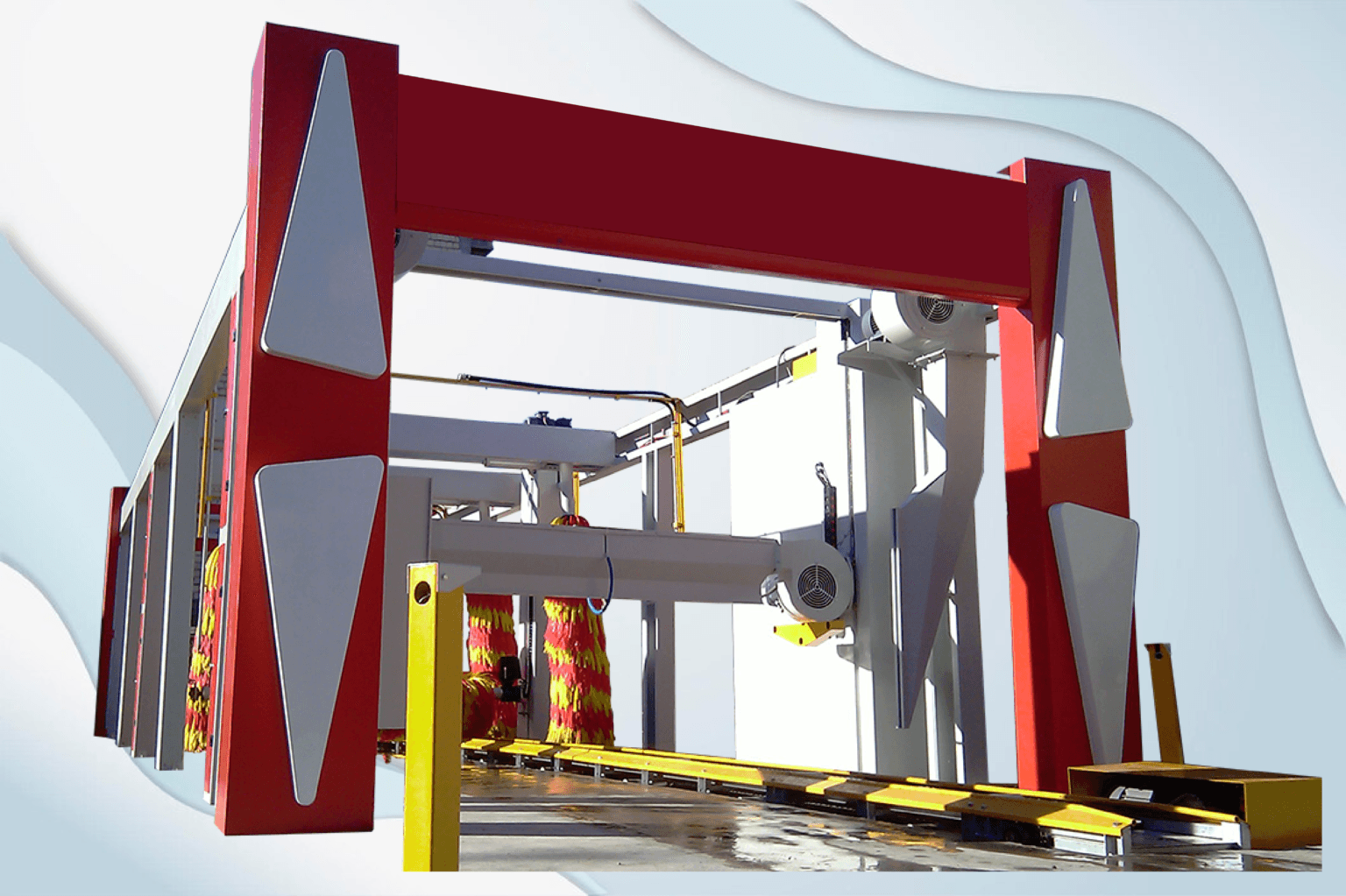

Keeping Uptime ≥98% with a 6-Month Warranty & Smart Maintenance: 7 Proven Tactics

Daily/weekly/monthly routines, spares strategy, remote support, and SLAs that keep your wash lane earning every hour.

Insights

Apr 22, 2025

1) Standardize daily routines

Walk-around inspection; check brushes/arms, hoses, rails, leaks.

Clean sensors and lenses; verify e-stops.

Empty grates and mud traps; log panel warnings.

2) Calibrate weekly

Nozzles, angles, and spray coverage.

Chemical dosing against water hardness and temperature.

Dryer blade spacing and timing.

3) Go deeper monthly

Lubricate bearings, check gearbox levels.

Rail/roller alignment and fastener torque.

Thermal scan (if available) on panels to spot hot connections early.

4) Build a “72-hour spares kit”

Keep on site: sensors, belts, nozzles, seals, key fuses/relays, a spare dosing pump, and common fasteners. The goal: fix in hours, not days.

5) Track the right KPIs

Uptime %, Cycle time, MTBF (mean time between failures), MTTR (mean time to repair).

Monthly trend reviews drive targeted maintenance and training.

6) Use your warranty wisely

Europe Makine’s 6-month warranty covers manufacturing defects (parts & labor). Pair it with a response-time SLA (e.g., 4/8/24-hour windows by severity) and remote diagnostics to accelerate troubleshooting.

7) Train for turnover

Create a 30-minute shift-start checklist, a 2-page quick reference for fault codes, and a quarterly refresher on chemical safety and emergency procedures. Training offsets staff rotation and keeps standards consistent.

The business impact

Each 1% uptime improvement in a busy site often equals dozens of extra paid washes per month.

Preventive maintenance is cheaper than lost queue hours and reputational damage.

CTA: Want a site-specific maintenance pack and spares list? Contact Europe Makine—we’ll map your usage pattern to a practical plan.

More to Discover

Keeping Uptime ≥98% with a 6-Month Warranty & Smart Maintenance: 7 Proven Tactics

Daily/weekly/monthly routines, spares strategy, remote support, and SLAs that keep your wash lane earning every hour.

Insights

Apr 22, 2025

1) Standardize daily routines

Walk-around inspection; check brushes/arms, hoses, rails, leaks.

Clean sensors and lenses; verify e-stops.

Empty grates and mud traps; log panel warnings.

2) Calibrate weekly

Nozzles, angles, and spray coverage.

Chemical dosing against water hardness and temperature.

Dryer blade spacing and timing.

3) Go deeper monthly

Lubricate bearings, check gearbox levels.

Rail/roller alignment and fastener torque.

Thermal scan (if available) on panels to spot hot connections early.

4) Build a “72-hour spares kit”

Keep on site: sensors, belts, nozzles, seals, key fuses/relays, a spare dosing pump, and common fasteners. The goal: fix in hours, not days.

5) Track the right KPIs

Uptime %, Cycle time, MTBF (mean time between failures), MTTR (mean time to repair).

Monthly trend reviews drive targeted maintenance and training.

6) Use your warranty wisely

Europe Makine’s 6-month warranty covers manufacturing defects (parts & labor). Pair it with a response-time SLA (e.g., 4/8/24-hour windows by severity) and remote diagnostics to accelerate troubleshooting.

7) Train for turnover

Create a 30-minute shift-start checklist, a 2-page quick reference for fault codes, and a quarterly refresher on chemical safety and emergency procedures. Training offsets staff rotation and keeps standards consistent.

The business impact

Each 1% uptime improvement in a busy site often equals dozens of extra paid washes per month.

Preventive maintenance is cheaper than lost queue hours and reputational damage.

CTA: Want a site-specific maintenance pack and spares list? Contact Europe Makine—we’ll map your usage pattern to a practical plan.