Industrial Fleet & Municipality Washing: Uptime, Water Reclaim, Safety—What Really Moves the Needle

Design for mixed body types, keep uptime ≥97%, save water with reclaim, and standardize safety to control total cost of ownership.

Tutorials

Apr 27, 2025

Complexity of fleet operations

Mixed geometries: Solo/articulated buses, mirrors & accessories, roof lines.

Peak windows: Depot waves create queues; cycle time and staging matter.

Hygiene standards: Public transit and food logistics add compliance layers.

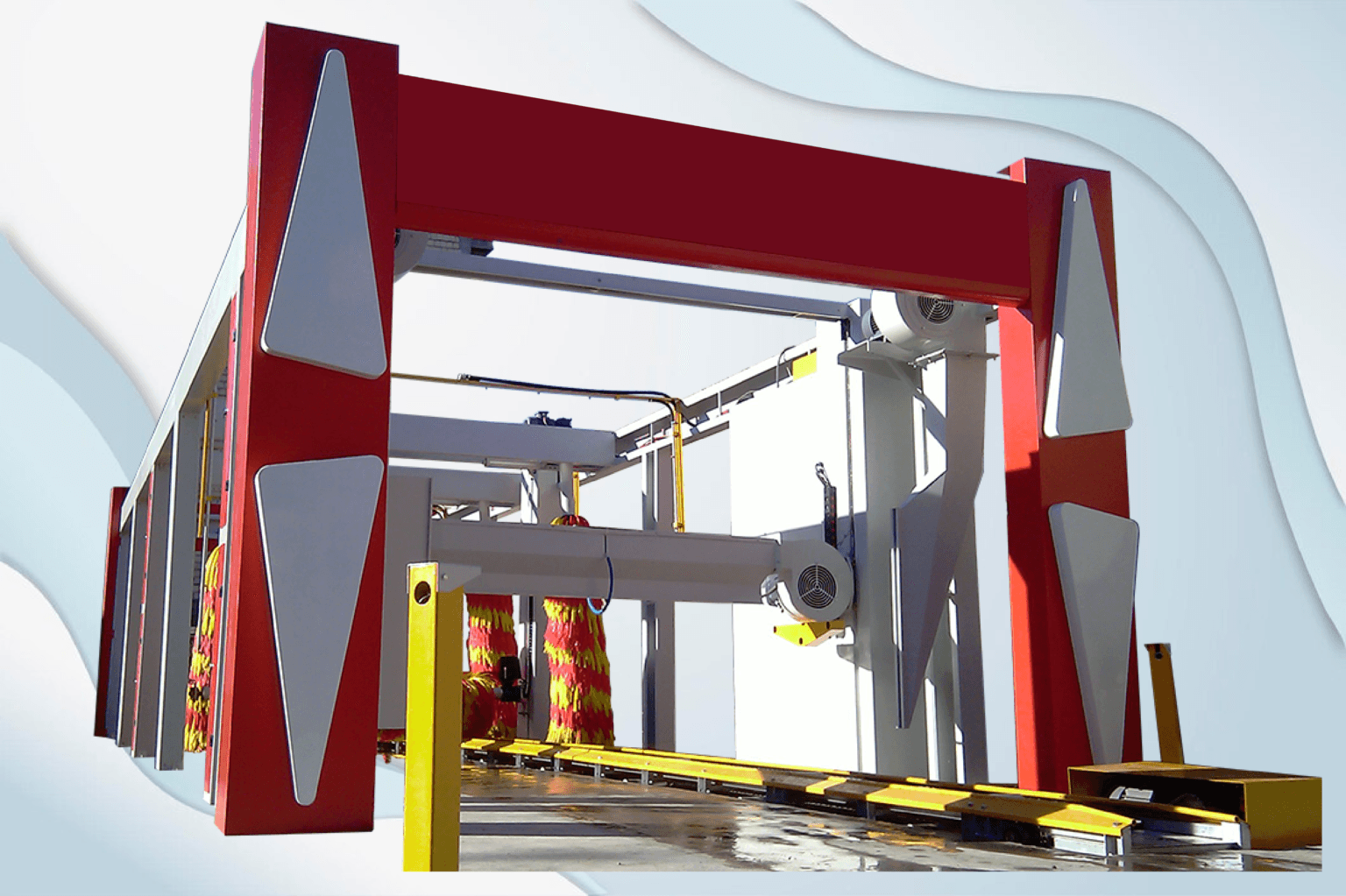

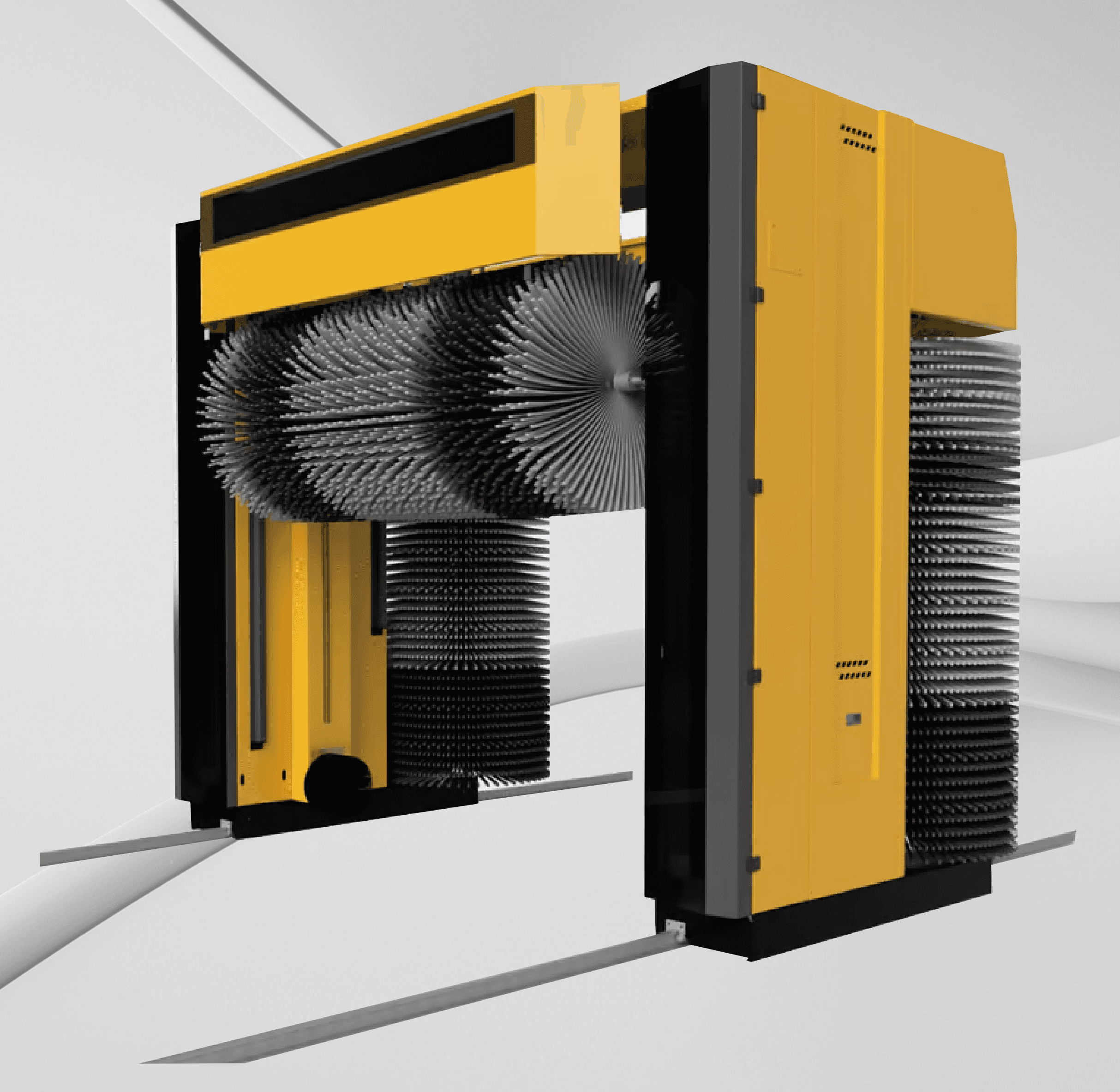

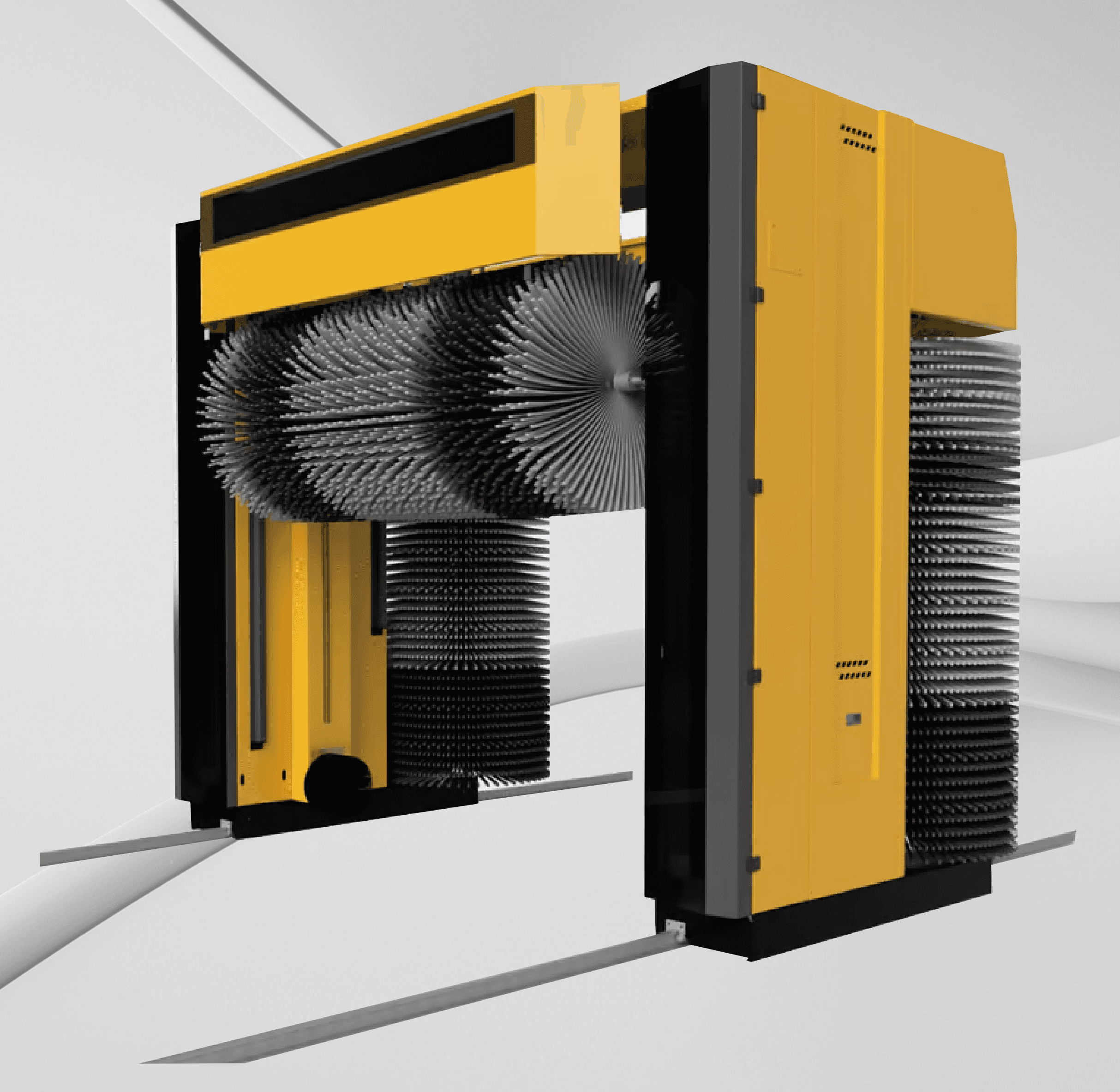

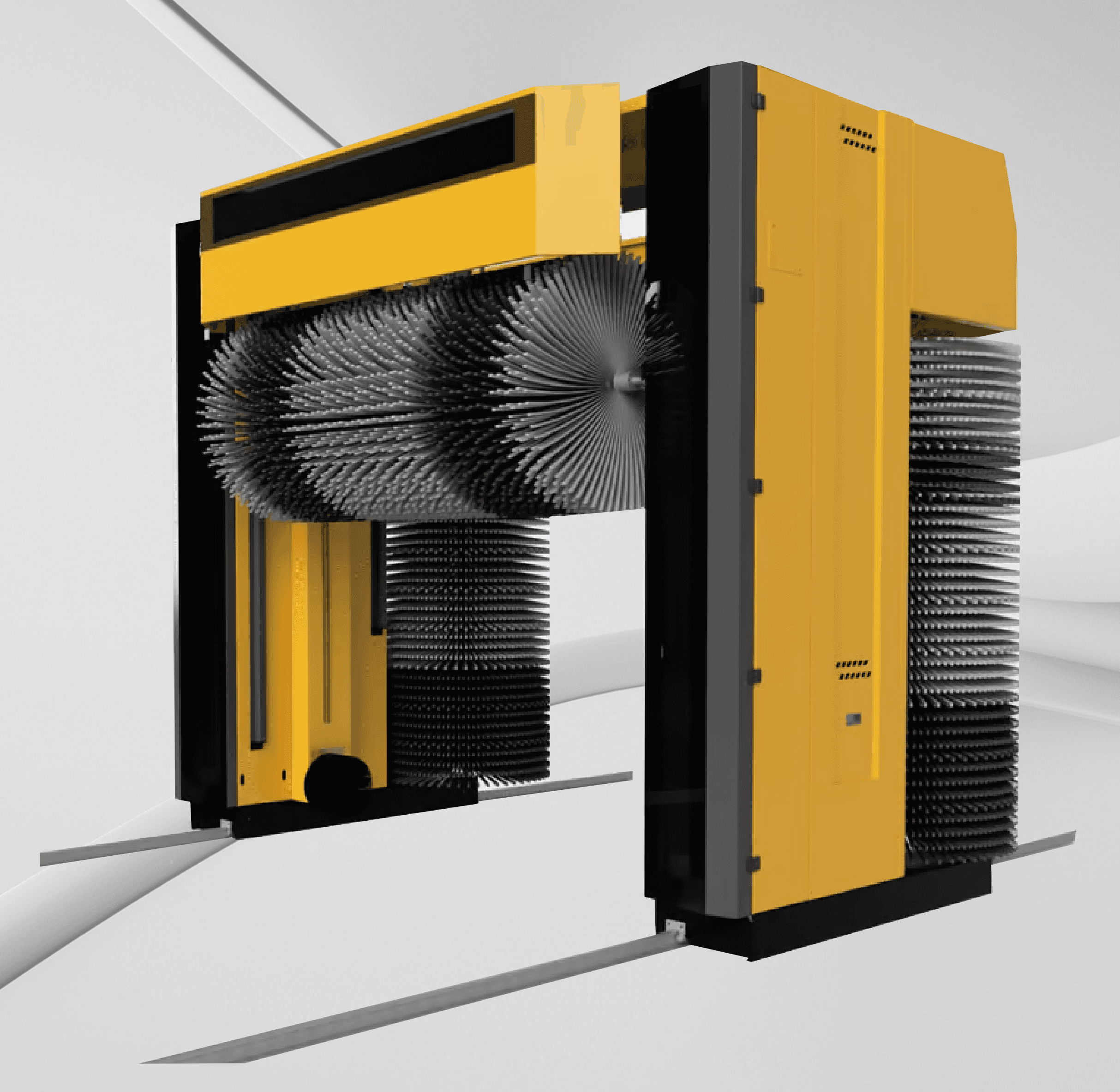

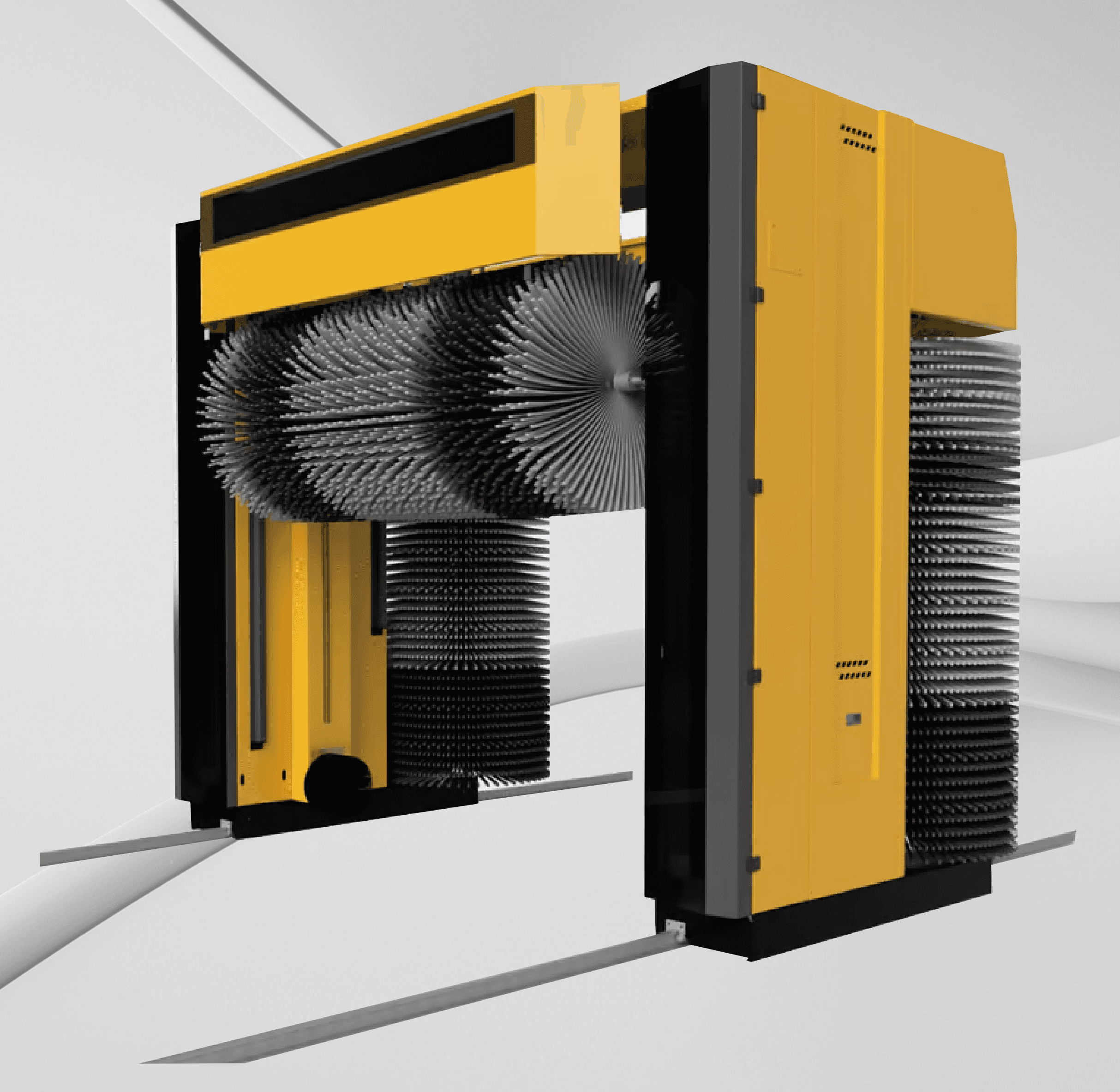

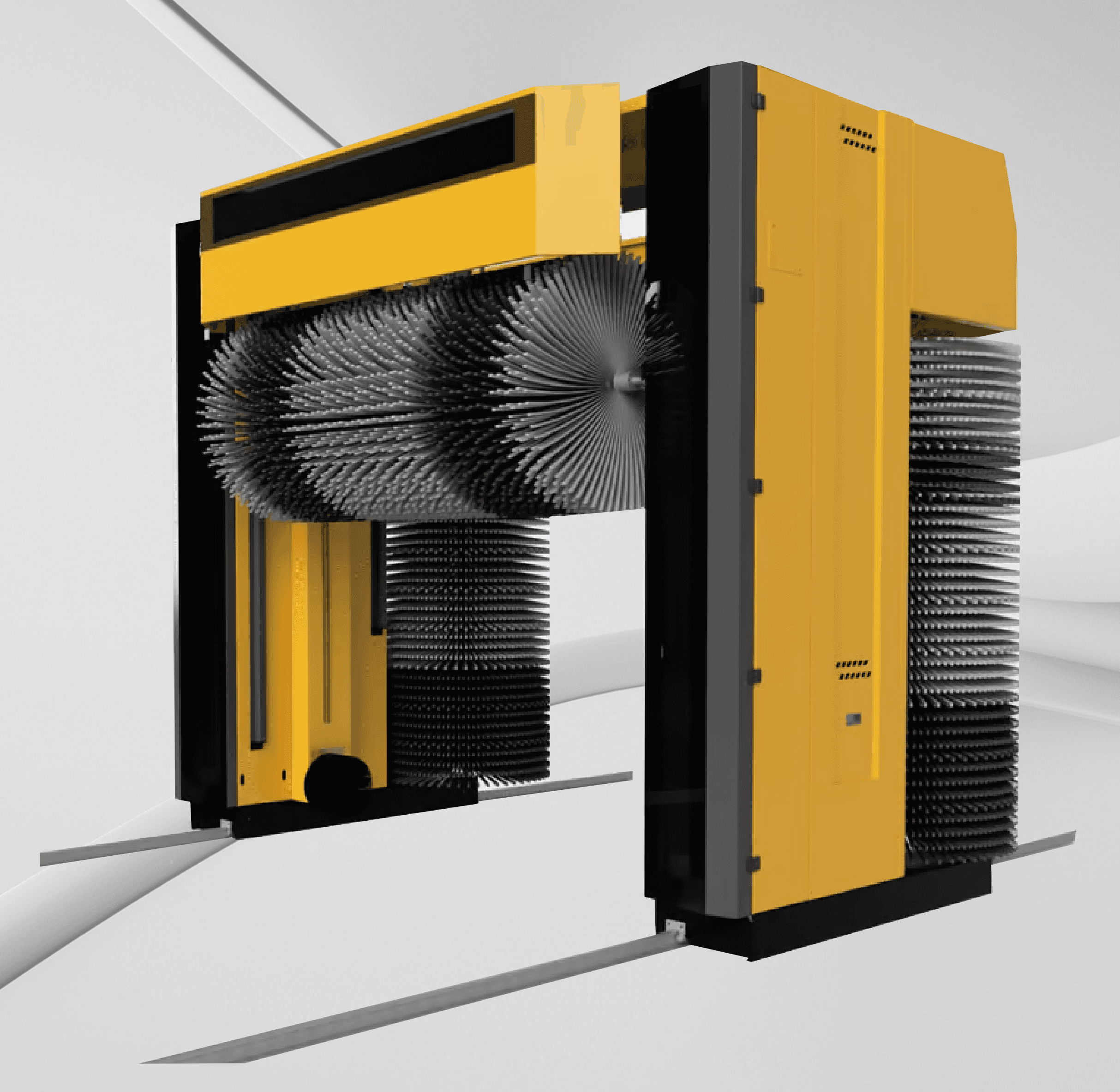

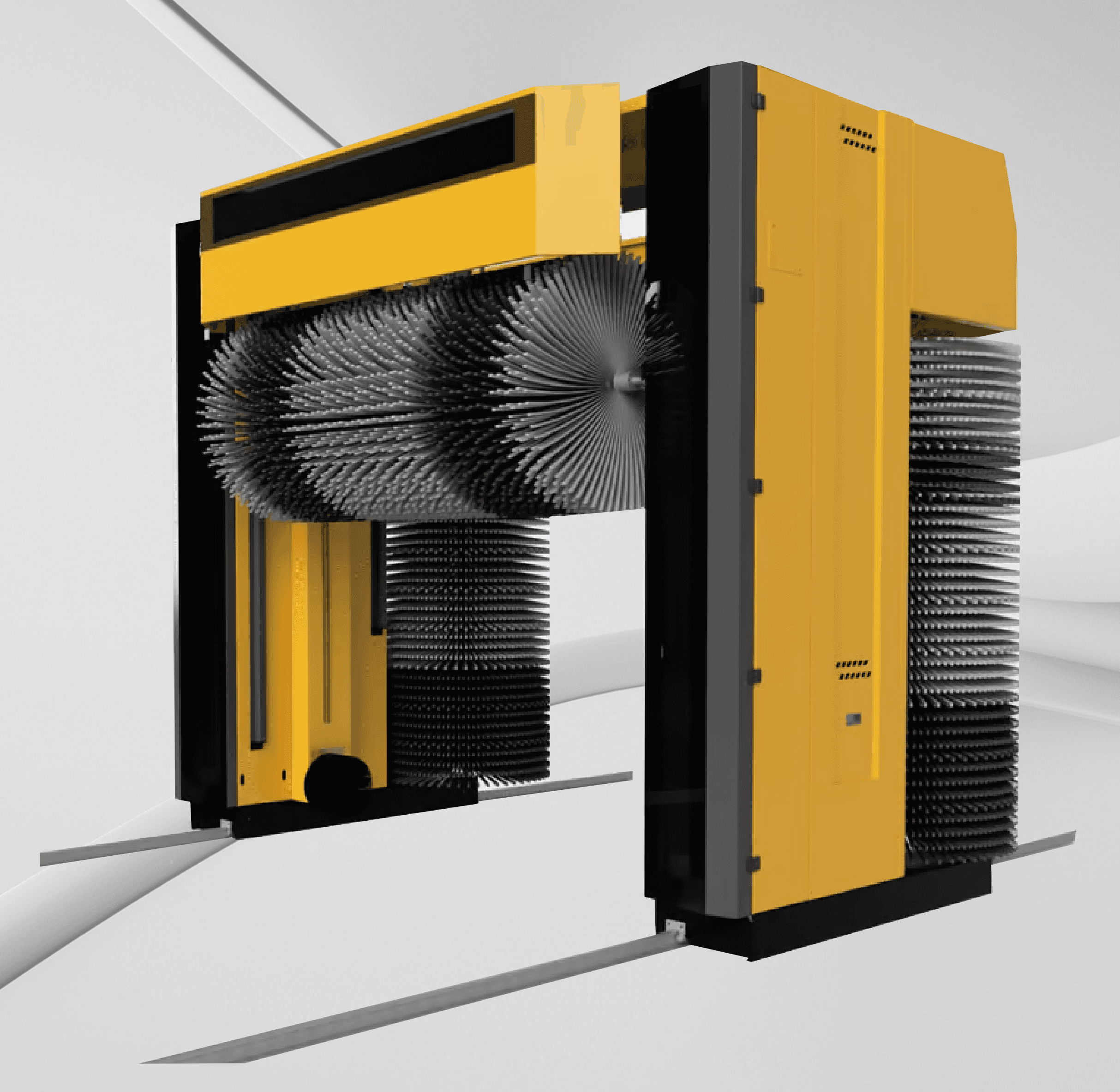

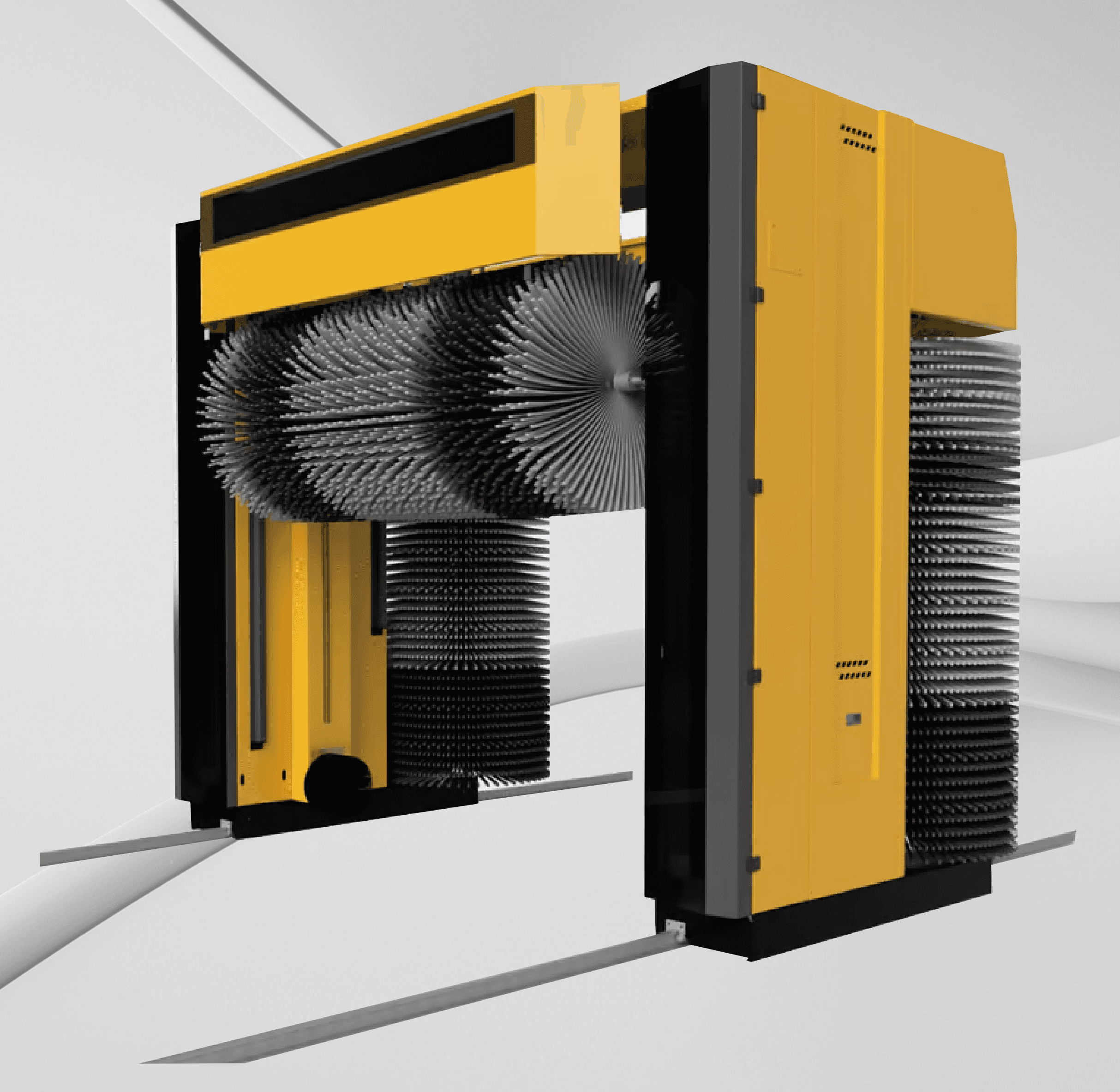

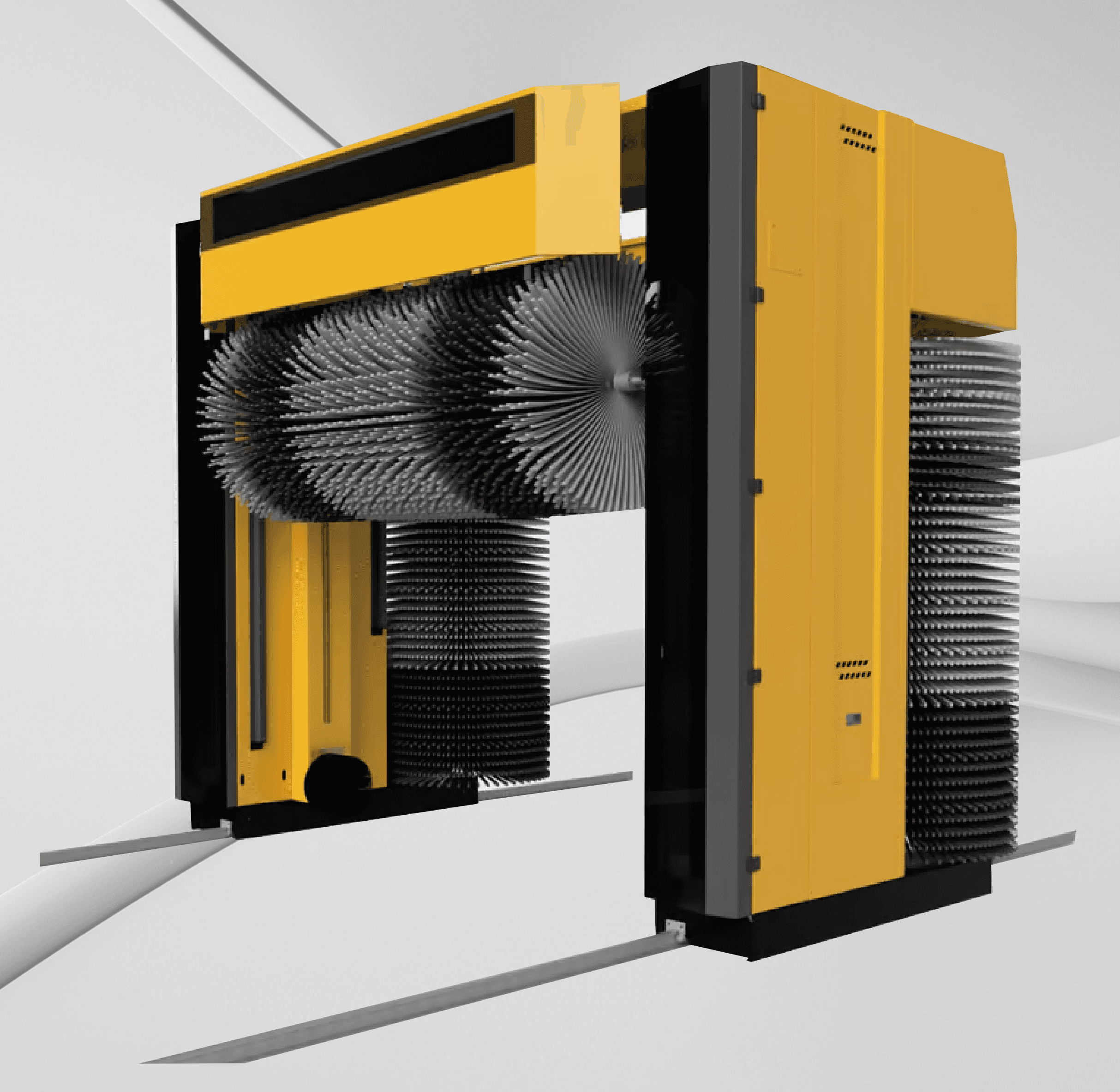

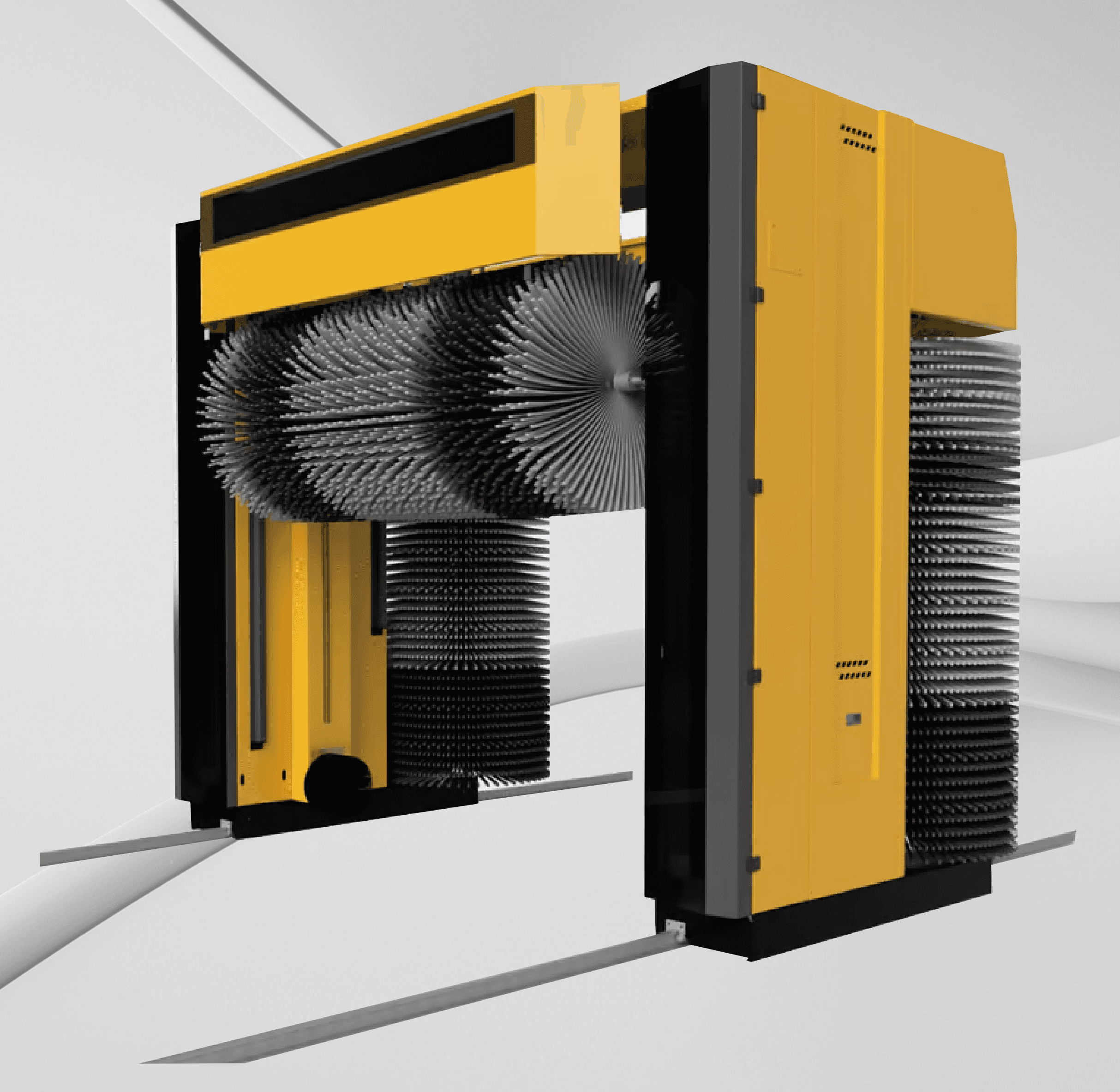

Configuration building blocks

Clearances & adjustability: Height/side allowances; programmable brush/robot paths.

Chemistry: Low-corrosion formulas; seasonal presets (salt, pollen).

Drying: Energy-aware dryers with adaptive timing.

Payments/telemetry: Depot integrations; ANPR for automatic logging.

Water & cost control

Reclaim systems: Capture, settle, filter → reuse; 50–80% water savings.

Unit cost target: $1.2–$2.0 per wash (varies by region and reclaim).

Cycle presets: Short/standard/deep to balance quality vs. queue length.

Uptime as the primary KPI

Aim for ≥97%. Two tools make it real: preventive maintenance and parts readiness.

Daily: Visual checks, leaks, grate cleaning, sensor wipe, e-stop test.

Weekly: Nozzles/angles, dosing calibration, dryer inspections.

Monthly: Bearings lubrication, rail alignment, vibration & noise check, panel thermal scan.

Spares to stock: Sensors, belts, nozzles, seals, key relays—your “first 72-hours kit.”

Example throughput model

Target: 25–60 buses/hr (config-dependent).

If your depot washes 120 vehicles/day × 26 days = 3,120/month, shaving 60 seconds off a cycle can free 50+ extra slots monthly—often the difference between overtime costs and smooth dispatch.

Safety & training

LOTO, MSDS handling, non-slip walkways, clear pedestrian routes.

Cameras/sensors tested per shift; documented checklists.

Signage & beacons to coordinate drivers and wash operators.

CTA: Operating a mixed fleet? Request a free bay audit to tune presets, reclaim, and queue logic for your depot.

More to Discover

Industrial Fleet & Municipality Washing: Uptime, Water Reclaim, Safety—What Really Moves the Needle

Design for mixed body types, keep uptime ≥97%, save water with reclaim, and standardize safety to control total cost of ownership.

Tutorials

Apr 27, 2025

Complexity of fleet operations

Mixed geometries: Solo/articulated buses, mirrors & accessories, roof lines.

Peak windows: Depot waves create queues; cycle time and staging matter.

Hygiene standards: Public transit and food logistics add compliance layers.

Configuration building blocks

Clearances & adjustability: Height/side allowances; programmable brush/robot paths.

Chemistry: Low-corrosion formulas; seasonal presets (salt, pollen).

Drying: Energy-aware dryers with adaptive timing.

Payments/telemetry: Depot integrations; ANPR for automatic logging.

Water & cost control

Reclaim systems: Capture, settle, filter → reuse; 50–80% water savings.

Unit cost target: $1.2–$2.0 per wash (varies by region and reclaim).

Cycle presets: Short/standard/deep to balance quality vs. queue length.

Uptime as the primary KPI

Aim for ≥97%. Two tools make it real: preventive maintenance and parts readiness.

Daily: Visual checks, leaks, grate cleaning, sensor wipe, e-stop test.

Weekly: Nozzles/angles, dosing calibration, dryer inspections.

Monthly: Bearings lubrication, rail alignment, vibration & noise check, panel thermal scan.

Spares to stock: Sensors, belts, nozzles, seals, key relays—your “first 72-hours kit.”

Example throughput model

Target: 25–60 buses/hr (config-dependent).

If your depot washes 120 vehicles/day × 26 days = 3,120/month, shaving 60 seconds off a cycle can free 50+ extra slots monthly—often the difference between overtime costs and smooth dispatch.

Safety & training

LOTO, MSDS handling, non-slip walkways, clear pedestrian routes.

Cameras/sensors tested per shift; documented checklists.

Signage & beacons to coordinate drivers and wash operators.

CTA: Operating a mixed fleet? Request a free bay audit to tune presets, reclaim, and queue logic for your depot.

More to Discover

Industrial Fleet & Municipality Washing: Uptime, Water Reclaim, Safety—What Really Moves the Needle

Design for mixed body types, keep uptime ≥97%, save water with reclaim, and standardize safety to control total cost of ownership.

Tutorials

Apr 27, 2025

Complexity of fleet operations

Mixed geometries: Solo/articulated buses, mirrors & accessories, roof lines.

Peak windows: Depot waves create queues; cycle time and staging matter.

Hygiene standards: Public transit and food logistics add compliance layers.

Configuration building blocks

Clearances & adjustability: Height/side allowances; programmable brush/robot paths.

Chemistry: Low-corrosion formulas; seasonal presets (salt, pollen).

Drying: Energy-aware dryers with adaptive timing.

Payments/telemetry: Depot integrations; ANPR for automatic logging.

Water & cost control

Reclaim systems: Capture, settle, filter → reuse; 50–80% water savings.

Unit cost target: $1.2–$2.0 per wash (varies by region and reclaim).

Cycle presets: Short/standard/deep to balance quality vs. queue length.

Uptime as the primary KPI

Aim for ≥97%. Two tools make it real: preventive maintenance and parts readiness.

Daily: Visual checks, leaks, grate cleaning, sensor wipe, e-stop test.

Weekly: Nozzles/angles, dosing calibration, dryer inspections.

Monthly: Bearings lubrication, rail alignment, vibration & noise check, panel thermal scan.

Spares to stock: Sensors, belts, nozzles, seals, key relays—your “first 72-hours kit.”

Example throughput model

Target: 25–60 buses/hr (config-dependent).

If your depot washes 120 vehicles/day × 26 days = 3,120/month, shaving 60 seconds off a cycle can free 50+ extra slots monthly—often the difference between overtime costs and smooth dispatch.

Safety & training

LOTO, MSDS handling, non-slip walkways, clear pedestrian routes.

Cameras/sensors tested per shift; documented checklists.

Signage & beacons to coordinate drivers and wash operators.

CTA: Operating a mixed fleet? Request a free bay audit to tune presets, reclaim, and queue logic for your depot.